What is Compact Laminate

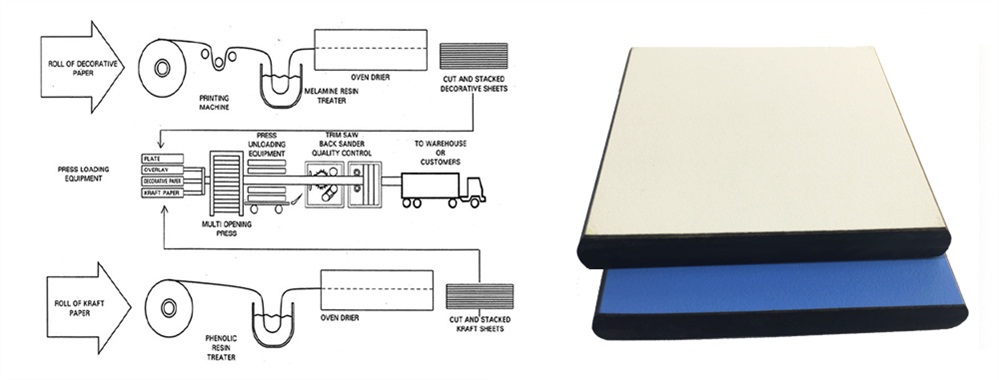

Compact laminate, also known as phenolic board and high pressure laminate. Generally, compact laminate can be considered as thick high pressure laminate boards.

by Port09

Compact laminate is constructed with decorative paper impregnated with melamine resin, plus multi-layered black or brown kraft paper impregnated with phenolic or urea-formaldehyde resin, layering, and then steel at high temperatures(150℃), high pressure(1430 psi) environment from repression. The layers are then sandwiched between laminated top and bottom sheets, compressed and baked.

1. Features

Compact Laminate has some unique features for its special production process, such as water-proof, fire-proof, anti-abrasion, easy to clean, durable and impact resistant, as it is widely used in toilet partition, locker, table, bench, wall cladding and kitchen cabinets.

2. Density

Compact laminate board is a kind of board with high density, it obtains 18kg/m3. Different from PVC panel or Metal panel, the high density means it doesn’t need edge banding. And it also brings a problem that compact laminate products are usually very heavy. It would take much efforts to move a wall cladding or compact laminate tables.

3. Color

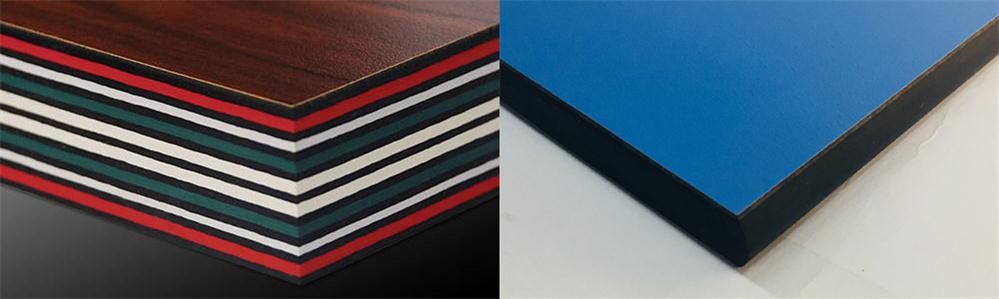

The color can be divide into to two parts, the surface color and the core color. When you are looking at a compact laminate panel, despite the colorful surface, the edge color represent its core color.

Compact laminate board gains hundreds of colors for surface, solid color like antique white and light gray gives a modern impression, wood grain color lead you to a classic world and suits the place with green topics well while marble color will lend a decorous feeling. By the way, compact laminate colored with digital print and engraving making the appearance more possibility.

For example, toilet cubicle stall doors in a kindergarten can be painted as pictures of animals, lockers in gym club can be painted any sports stars you want and engraving the door numbers on locker doors for its never being lost. As you can see, compact laminate gains a large application area and it can be used as a decoration material.

The compact laminate we made is black core. The color of core springs from the kraft paper used in the production process. Numbers of kraft paper extruded together to make sure the compact laminate produced would be tough, while also making the inner core in a dark color. So generally, the compact laminate you see are normally in black. That accidentally infers that the compact laminate is quite hard.

But we could still find out some compact laminate panels with white or colorful core. This kind of compact laminate is mainly used for decoration for its good-looking edge. But compared to standard black core panel, the colorful one are less strong and easier to deformation. More important, it’s more expensive.

4. Function

Compact laminate panel is extremely widely used in many places as its strong features. Indoor, outdoor, medical and research use. Here are 4 main applications we made for our customers for you to refer.

For toilet cubicle and lockers

For toilet cubicle and lockers

A public bathroom might be a hotbed for bacterial. If you want your bathroom to clean while take less efforts to clean it. That requires the material to be water-proof, anti-bacterial and easy to clean. Compact laminate just get want you need. What about other materials? Wood? No one would consider wooden toilets. Metal? Only metal alloy, like stainless steel, zinc alloy and aluminum alloy are qualified, but the color and cost might be a problem. Color range for a metal material is obviously low. If you want to add more color on a metal material, you may have to place another material as the surface. What about other common materials like particle board and HDPE? They are also popular these years, but HDPE and particle board are less strong and with a shorter lifespan than compact laminate board. If you are considering saving budget, these materials might be better.

For exterior

Outdoor conditions are more complex than indoors. An outdoor material needs to face the changing temperature, the sunlight, the rains and even the unpredictably impact from nowhere. Compact laminate with anti-UV coverage could handle these problem. As for other materials, only the best wood and metal alloy material can provide a good service experience.

For Lab

Laboratory usually use ceramics or glass as counter tops as these materials are stable and resistant corrosion, knock and seismic. Compact laminate is also used as table tops in labs and medic. A compact laminate is already anti-corrosion itself, with a coverage of anti-knock and anti-seismic function.

For kitchen cabinets

Kitchen cabinets get a special requirement on materials. The material used needs to be easy to clean and maintain. In a proper temperature, compact laminate can be bend when in production to fit most situations. While the surface of compact laminate touches smooth and it would be good for making an cabinet.

5. Lifespan

The service time of a compact laminate board is usually 10 to 15 years, if the product is maintained well, it might serve for over 20 years. But most of the time, the accessories can’t hold for such a long time. So, choosing accessories in good quality is also a problem worth to talk. But that’s not what we are talking about now. Normally, serving for over 10 years is enough. 10 years is long enough for a place to refresh its design style. As it’s much shorter for you to change you iPhone.

6. Recyling

As the compact laminate is in high density and fire-proof, it is hard for a compact laminate board wasted to be recycled or let it natural degrading itself. So the compact laminate wastes needs to be collected and sent to smelting plant into industrial incinerator, the compact laminate would be burned under the high temperature of industrial incinerator.

This is the brief introduction of compact laminate board. It is not a perfect material, but it had proved itself to be powerful and reliable. We had been a compact laminate manufacturer since 2001 and making compact laminate boards for over 16 years.